How to Ensure Compliance

& Performance

Understand key tolerances and their thresholds to obtain better service delivery outcomes and enhance compliance.

TL:DR – Key Takeaways

- What are Tolerances?: Tolerances provide flexibility in maintenance schedules, allowing facility managers (FMs) to address real-world challenges such as resource constraints or delays without compromising compliance or safety.

- Cost Control and Efficiency: Preventative maintenance based on tolerances helps avoid costly emergency repairs and downtime. By maintaining systems within prescribed tolerances, facilities reduce operational risks and prolong the life of equipment.

- Key Tolerances Within Australian Standards: Learn the key tolerance thresholds incorporated into Australian standards to obtain best practice for your maintenance schedules. See how you can capture tolerance compliance for better practice in the short and long term.

What Are Tolerances & Why Are They Important?

Facility managers have the tough job of trying to balance the demands of tight maintenance schedules ensuring compliance with relevant Australian standards. Tolerance has emerged as a critical mechanism, allowing for flexibilty without compromising compliance or safety.

When tasks are delayed or missed, the risk of equipment failure and safety hazards increases significantly. Tolerances effectively ‘bridge the gap’ between ideal timelines and real-world challenges to ensure the critical maintenance of assets and delivery of tasks, whilst guaranteeing compliance. They can be seen as acceptable limits of variation that allow equipment/assets to keep working safely and effectively, even when things aren’t exactly perfect.

The Critical Case For Tolerances

Maintenance schedules are often difficult to meet due to contractor resource constraints, logistical delays in service delivery, budget constraints, or insufficient contractor behaviours. This can result in delayed or missed tasks, increasing the risk of equipment failure, lack of compliance and adidtional maintenance costs.

To address these challenges tolerances were introduced into the Australian Fire Safety Standards during 2005. Since then, tolerances have been incorporated into industry standards to ensure service providers deliver maintenance as required whilst compliance is still held. Tolerances address the practical realities of asset maintenance scheduling, providing a grace period to allow maintenance activities to be performed without compromising their compliance requirements.

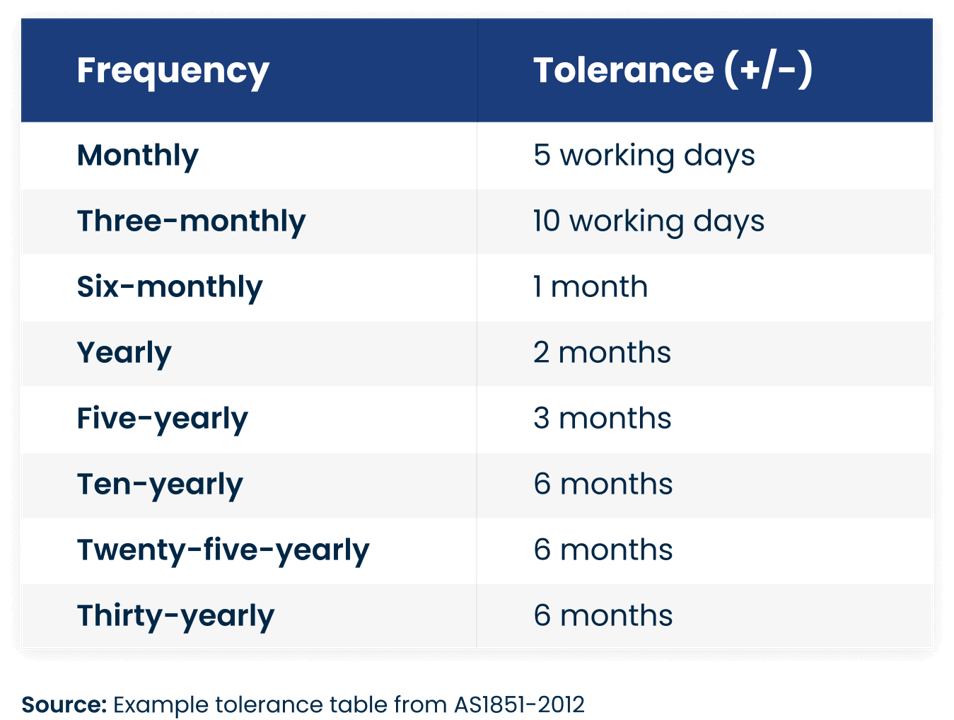

The table on the right outlines critical tolerance timing thresholds for preventative maintenance as documented within AS1851-2021, with the key takeaway being that these thresholds are dependent on the frequency of work to be performed.

The Key Benefits of Tolerance Adherence

Understanding, tracking, and analysing adherence to tolerance levels helps mitigate risks and ensures assets and systems remain functional and safe. Therefore, the benefits include:

- Proof of Service Delivery with Risk Mitigation: Maintenance tasks completed within acceptable tolerance timeframes, reduce the risk of equipment failure and safety hazards. This allows businesses to remain compliant while adapting to unexpected challenges, such as resource constraints, unforseen delays, or complete delivery failure.

- Cost Savings: By providing flexibilty in maintenance scheduling, tolerances help service providers plan and allocate resources more efficiently, reducing the likelihood and frequency of costly emergency repairs due to delayed or neglected maintenance. FMs can contractually embed these requirements and ensure payment only for tasks that meet standards.

- Demonstrated Regulatory Compliance: Tolerance management ensures adherence to maintenance regulations and standards, as well as your contract.s

Maintaining Compliance – Key Standards & Associated Tolerances

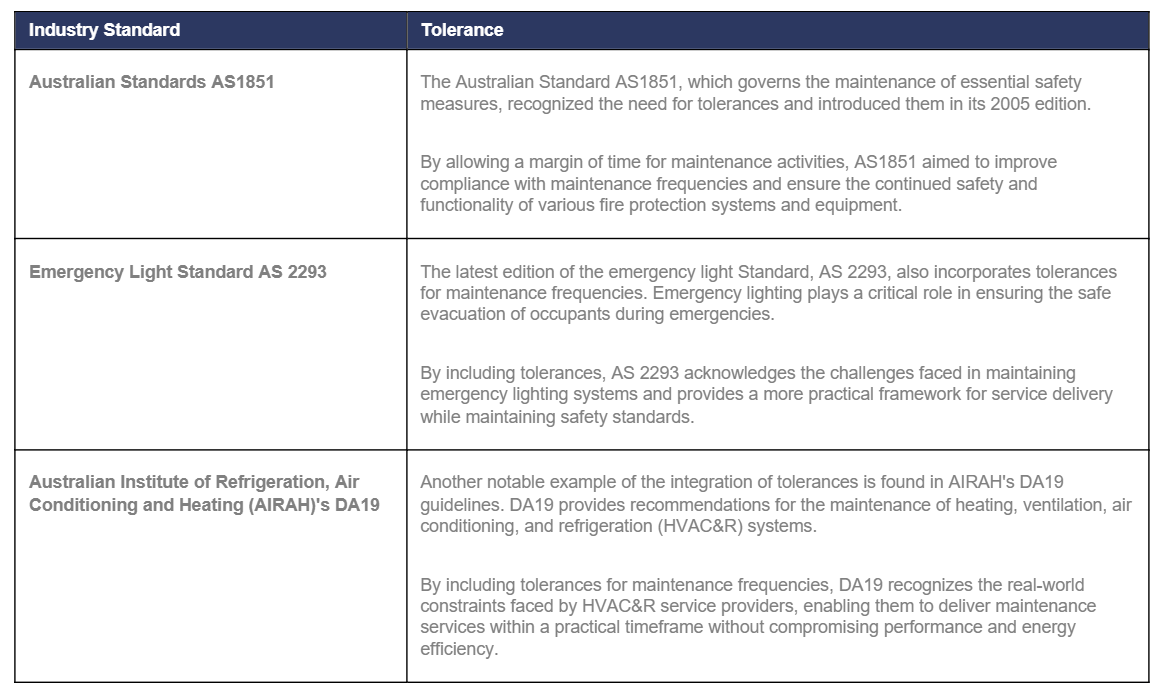

Industry best practices in facilities management and compliance with Australian standards continue to evolve, particularly in the integration of tolerances. By refining maintenance schedules with built-in tolerances, these standards allow for greater flexibility, ensuring that compliance is maintained without sacrificing operational efficiency or safety. This comes with the ability to hold your contractors accountable for insufficient work.

The table below highlights key Australian Standards related to facilities maintenance and preventative maintenance, detailing the associated tolerances and their practical impact.

By incorporating tolerances into maintenance standards, Australian industry bodies have taken a proactive step toward ensuring a balance between compliance and practicality. The integration of tolerances allows for realistic maintenance practices while maintaining safety, performance, and efficiency in various building systems. It is through such adaptations that the industry can continue to evolve and meet the demands of a changing landscape while ensuring the well-being and functionality of our organisational environments.

Talk To an Expert

Facility managers can leverage tolerances to simplify maintenance schedules, making their jobs easier while ensuring the safety and compliance of the sites they manage. For further insights into tolerance adherence, we invite you to reach out to Glenn Talbot, Managing Director, and founder of Verified. Glenn serves as the independent Chair for the Australian Standards Committee FP-001, the body behind the development of AS1851, and is a leading expert within the industry. You can contact us to chat with Glenn via email or call on 1300 133 950.